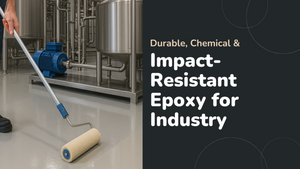

In Industrial and manufacturing environments, floors are constantly exposed to abrasion, chemical spills, heavy equipment, and mechanical impacts. Ordinary flooring materials like cement, tiles, or vinyl simply don’t hold up in the long term.

To ensure safety, durability, and low maintenance, industries are now turning to heavy-duty epoxy resin coatings—and Magnifico 12H Resin is engineered specifically for this purpose.

The Industrial Challenge: What Floors Endure

Industrial facilities—like factories, pharmaceutical units, chemical plants, workshops, and warehouses—face daily challenges:

- Chemical spills from oils, acids, solvents

- Heavy impact from dropped tools and machinery

- High foot traffic & forklift movement

- Thermal shocks and moisture intrusion

- Slippery or unsafe surfaces

Why Magnifico 12H Resin is Built for Industrial Performance

Magnifico 12H is a high-performance epoxy coating system developed by Magnifico Resins to meet the extreme demands of industrial spaces. Here’s why it stands out:

1. Chemical Resistance at Its Core

Spilled acids, solvents, oils, or cleaning agents can quickly corrode or stain traditional flooring.

Magnifico 12H Resin resists:

- Strong acids & alkalis

- Grease and oil

- Solvents & industrial cleaners

- Corrosive liquids used in factories and labs

2. Impact & Abrasion Resistance

Whether it’s dropped tools, shifting pallets, or wheeled equipment—industrial floors take a beating.

Magnifico 12H Resin offers:

- Superior compressive strength

- Crack and chip resistance

- Anti-abrasive surface durability

3. Thermal & Moisture Protection

Fluctuating temperatures and damp conditions can ruin flooring—especially in food plants or cold storage.

Magnifico 12H is:

- Moisture-tolerant during and after curing

- Resilient under thermal cycling

- Waterproof, sealing out corrosive agents

With a seamless, non-porous finish, 12H Resin-coated floors resist dust, stains, and microbial growth—ideal for pharmaceutical or FMCG units that require hygiene and sanitation.

Technical Highlights of Magnifico 12H Resin:

- Mix Ratio: 2:1

- Pot Life: 60–90 minutes

- Cure Time: 12 hours (touch dry), full cure in 24 hrs

- Surface Finish: Glossy to semi-gloss, based on topcoat

- Coverage: ~10 sq. ft/kg per coat (varies with substrate)

Magnifico 12H is ideal for:

- Factory floors (textile, steel, pharma, chemical)

- Workshops & machine rooms

- Warehouses & loading docks

- Tool rooms & CNC floors

- Automobile & service stations

- Chemical storage and battery charging areas

- Surface Prep: Remove dust, oil, and moisture. Concrete should be ground for best bonding.

- Mixing: Mix resin and hardener thoroughly in a 2:1 ratio.

- Application: Use roller or trowel for even spread.

- Optional Topcoat: Apply anti-slip or UV-resistant topcoat for added performance.

- Cure Time: Walkable in 12 hours, fully cured in 24 hours.

- Decade of formulation expertise

- 100% Made in India

- Technical support for on-site applications

- Affordable large-scale industrial supply

- Trusted by professionals across India

Industrial flooring is not just about strength—it’s about longevity, safety, and protection under harsh working conditions. With Magnifico 12H Resin, you get a specialized solution that’s:

- Chemical Resistant

- Impact Resistant

- Thermally Stable

- Waterproof & Seamless

- Easy to Maintain